vTNC7 and Digital Twin: A powerful combo

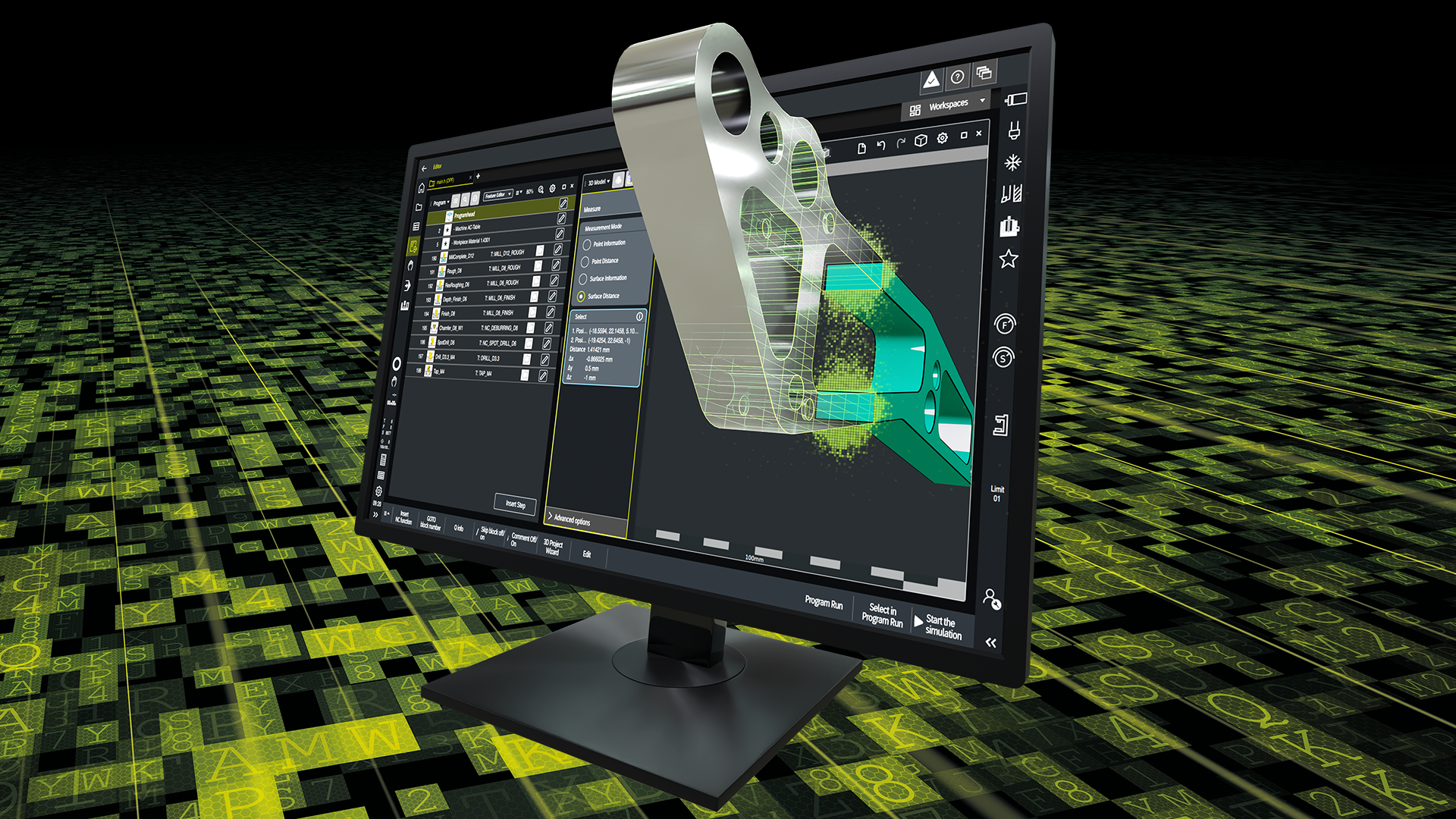

Through our “Digital Twin for vTNC7” service, multiple virtual machine models can be stored in the programming system and used for program simulation.

Users can select a virtual machine at the click of a mouse. The vTNC7 programming system then automatically adjusts itself to the kinematic model and other machine parameters in the background while keeping the same user interface and functionality. Users benefit from a consistent and efficient work experience.

Another vTNC7 highlight is its Feature-Based Programming function, which, for the first time, empowers users to create complete NC programs from 3D models. The user simply imports a CAD file and defines the datum, blank, and planes with just a few clicks. The automated feature finder detects the milling and drilling operations, even under tilting. The identified features can then be enriched with a previously defined machining strategy. The vTNC7 software automatically calculates the required paths. Cycles and Klartext syntax can be inserted at any time. If desired, an AI assistant can provide tips and even programming suggestions.

And the vTNC7 can do more: Its Klartext Converter converts NC programs created via Feature-Based Programming into pure Klartext, thus making them readable by predecessor controls to the TNC7 and therefore usable on older machines.